Written by Glenn Eckert | Layfield Geosynthetics

Occasionally geomembranes fail, requiring repair for a small leak or tear. When this happens, a trained technician must determine the geomembrane type and appropriate welding procedure. Sometimes, this is not a viable option due to a job site’s remoteness, seasonal issues, timing, or the severity of the damage. This technote offers suggestions to manage the situation until the leak or tear can be fully repaired.

The first step in any liner repair is to isolate, clean, and dry the area around the tear. Once the area is adequately prepared, it may require no more than a section of tape to be placed over the small rip or tear. Often, a strip of tape over the damaged area will be all that is required. Layfield distributes single-sided geomembrane repair tape in a 6″ width.

For larger tears, Layfield suggests using the “Band-Aid” approach. In this technique, a section of the geomembrane is used as a patch over the damaged area. The geomembrane patch can be salvaged from a non-critical section of the geomembrane or sourced directly from Layfield. This technique uses a taped seam rather than welding. The repair patch does not necessarily need to match the damaged geomembrane material precisely.

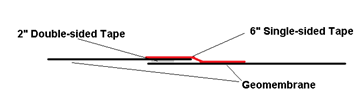

The damaged area is again isolated, cleaned, and dried; the area requiring cleaning must equal the area of the geomembrane patch, plus 3-4″ around the circumference to ensure a clean surface to maximize the tape adhesion. 2″ double-sided tape is applied to the perimeter of the patch. The patch is placed down over the damaged section, similar to using a Band-Aid on a skinned knee. Layfield suggests placing an additional strip of geomembrane repair tape centered over the flat seam as an added insurance layer.

If the area under repair is relatively flat, Layfield suggests placing a compressive load over the area to secure a leak-proof seal. A few shovel loads of gravel or a 2′ x 2′ cement paving block available from hardware stores would be an excellent choice.

Only use these techniques as temporary measures until a trained Layfield technician can adequately address and repair the damaged geomembrane. Layfield technicians are fully trained in all aspects of geomembrane installation, welding, and testing of geomembranes.

Related Articles

View All News