By Andrew Lees, Senior Application Technology Manager, Tensar Corp.

Recently, President Joseph R. Biden hosted a virtual Leaders Summit on Climate—proof, if any is required, that sustainability continues to be a key issue around the world. The summit focused on reductions in emissions, as well as several other global issues that impact climate change. One of the major concerns in the construction sector, for example, is the use of nonrenewable resources, including aggregates, and another focus is plastics. And yet the two issues are more closely linked than people realize.

The downside of plastics

Plastics, as we know them have been used for approximately 100 years. In that time, very few of the plastics created will have completed the natural degradation process due to the chemical structure of their makeup. In the last 70 years, an estimated 6.9 billion tons (6.3 billion tonnes) of plastic have been produced worldwide, with just 20% of this being recycled or incinerated. Consequently, large volumes of plastic waste have entered the environment, and this impacts ecosystems and has other key sustainability concerns. Single-use plastics, and those which will eventually be thrown away, can indeed be seen as having a significant downside.

In defense of plastic geosynthetics

It is ironic then, that one family of plastic products—geosynthetics—should be able to achieve so much in working toward the protection of the environment. Geosynthetics have now been used in the construction of infrastructure projects for more than fifty years: they extend road service life, conserve water resources, minimize land disturbance, control soil erosion and protect groundwater. They also reduce on-site excavation and fill placement, which in turn reduces the requirement to transport bulky construction materials, facilitates faster and simpler construction, extends infrastructure design life, and reduces maintenance requirements.

Geogrids

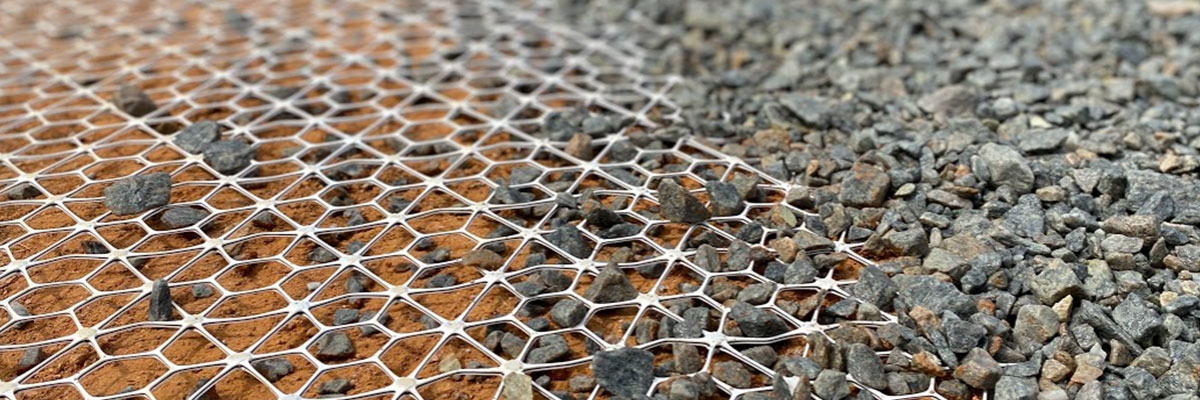

As well as this impressive list of advantages for geosynthetics, much of the environmental benefit accrued involves the reduction of aggregate needed for road and rail projects, as this is environmentally very expensive to extract, transport and place. Geogrids were invented in the late 1970s and can considerably reduce aggregate usage and minimize environmental impact. Geogrids can reduce the need for such quantities of aggregate in construction—specifically, in many cases, road pavement construction.

Geogrids can provide significant cost savings at the point of construction: They reduce the number of earthworks needed for engineering projects, and they accelerate construction and improve long-term performance, facilitating lower incidences of repair and the associated disruption. An appropriate geogrid used in a well-designed earth-retaining structure or pavement will combine the use of plastic, with the least amount of resource (such as aggregate, concrete or asphalt) to support the maximum life of any structure.

To return to the road pavement construction example, the amount of materials in the capping layer of a road pavement—usually aggregates or cement stabilized soils—can be reduced by the inclusion of a geogrid. This means less production impact, less initial transport emissions and less need to repair and maintain surfaces in the future—again, minimizing environmental impact. The incorporation of geogrids in the subbase layer of a road also enables a reduction in the thickness required. In this way, geogrids can strengthen and stiffen compacted aggregate layers to such an extent that they exhibit better load-bearing performance than layers twice as thick, built only with aggregate.

What role can plastics and geogrids play in sustainability?

Plastics fall into several categories: some are polluting our environment and will cause ecological problems for the future. Others—such as geosynthetics—are a solution rather than a problem. When correctly produced and utilized, they support a sustainable way forward that must be considered in future design projects, in all fields.

This article originally appeared on the Tensar Americas Blog, https://info.tensarcorp.com.

Related Articles

View All News